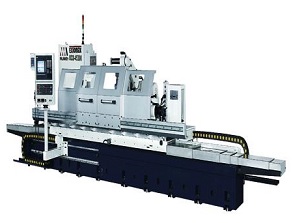

Standard Accessories:

1. Optical Scale (For X Axis & C Axis)

2. Tool and Kit x 1set

3. Hydraulic Tank with Oil Cooler x 1set

4. Grinding Wheel and Grinding Wheel Flange x 1set

5. Carbide Tipped Work Centers x 2set

6. Work Lamp x 1set

7. Diamond Tool Holder (Table Mounted Type) x 1set

8. Coolant Equipment x 1set

Optional Accessories:

1. Cam Locked Driving Dogs

2. Magnetic Collant Separator

3. Auto In-Process Gauge

4. Diamond roller dressing device

5. Work Holder (2 pcs / set)

6. Magnetic and Paper Filter

7. Gao Control

8. CBN Wheel

9. 2-point Steady Rest

10. Automatic Grinding Wheel Balancer

11. Oil Mist Collector

12. CAD/CAM Software

13. Adjustable 3-point Steady Rest

14. Semi-Auto. Grinding Wheel Balancer

15. Fully Enclosed Splash Guard

16. Adjustable 3-jaw Scroll Chuck

17. Wheel Balancing Stand and Arbor

18. Spare Grinding Wheel ad Grinding Wheel Agnle

19. Adjustable 4-jaw Chuck

20. Touch probe Gauge

21. Hydraulic Tailstock